Production program

HYDRAULIC GEAR PUMPS AND GEAR MOTORS

The gear pumps from Jihostroj a.s. are modern high pressure hydraulic pumps with variable connecting dimensions and styles according to international standards. They have continuous working pressure up to 300 bar (4360 psi). The hydraulic gear pumps are produced in thirteen interrelated series (X, P23, J, T3, UD, Q2, and heavy duty pumps: QHD0, QHD1, QHD2, GHD0, GHD1 and GHD2, and low noise gear pumps CQ3-T3T) which have displacement from 0.18 to 150 ccm/rev (from 0.01 to 9.15 in3/rev). We offer all the pumps of series P23, J, T3, UD and Q2 in reverse models or as hydraulic motors, they can have special shaft sealing resistant to 10 bar (145 psi). The hydraulic gear pumps are produced in a wide range of modifications for various usage in hydraulic power packs, mobile machines with power circuits or power steering. They can be used in construction,

agricultural machines, in fork lifts, excavators, etc. The hydraulic pumps can be equipped with front-end bearing absorbing radial and axial forces of the drive. The hydraulic gear pumps from Jihostroj can be used also as tandem pumps, all the series can be combined in a double or triple (in special cases in four or five pumps systems) modifications. They are applied especially in complicated hydraulic circuits of vehicles and manipulation machines, where they have an advantage of saving space and a number of drives of the pumps.

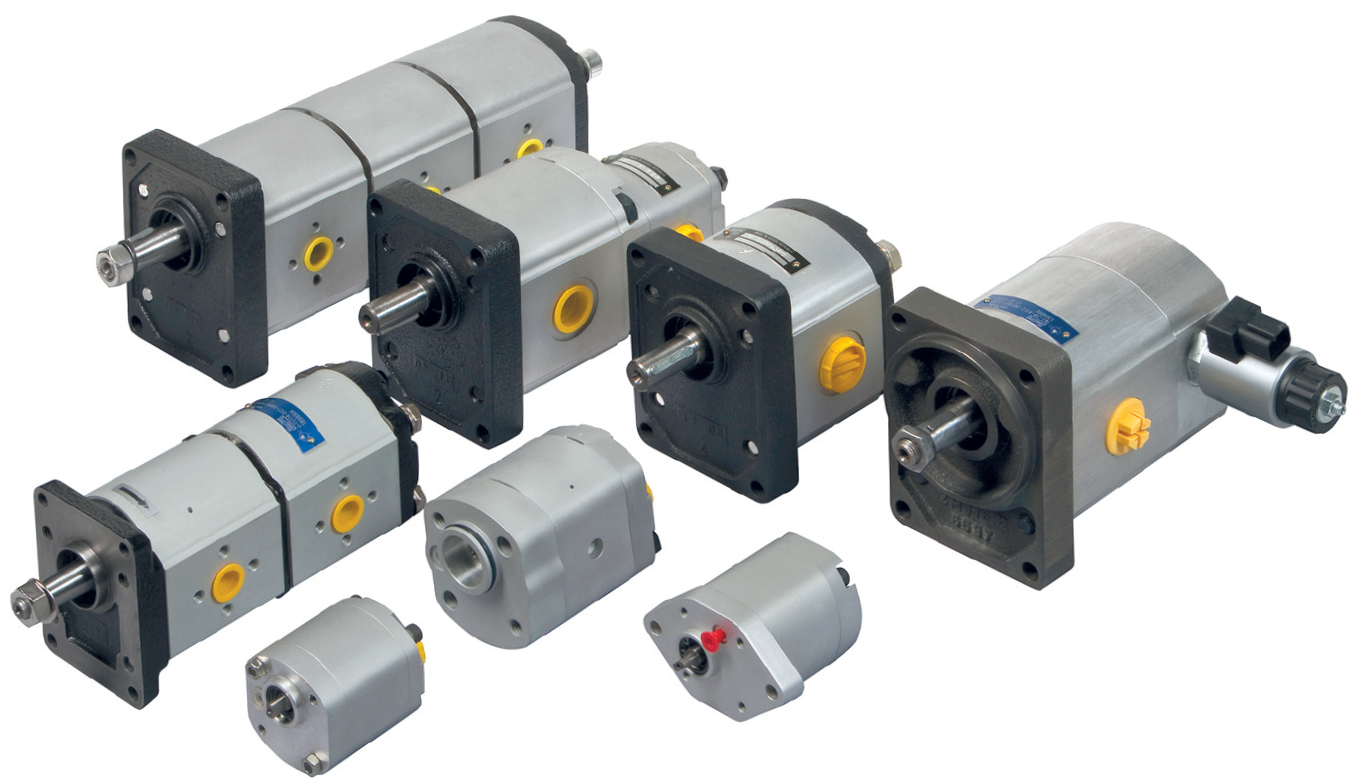

ALUMINIUM HYDRAULIC GEAR PUMPS

- Displacement from 0.18 to 100 ccm/rev

- (0.01 to 6.10 in3/rev)

- Intermittent Pressure up to 310 bar (4500 psi)

- Continuous Pressure up to 290 bar (4210 psi)

- Revolutions up to 8000 RPM

- Popular drives and ports

- Integral relief valves

- Straight or helical gears

- Full aluminium construction

- Combination aluminium – cast iron construction

- Multiple pumps on one shaft design

- High efficiency

Pumps with external gears are applicable for their simple design, compact dimensions and wide range of types and modifications. They are used in modern hydraulic systems, handling technologies and mobile hydraulics. Basic design is composed from standardized parts.

The body of the pump is produced from cast iron or aluminium alloy. All flanges, inlets and outlets (located on the side – in the body, or axial – in the cover) comply with world standards. Gear wheels are optimized to achieve a low noise level, they are made of high-strength steel. Wheel journals with high quality surface are in bearings, which are constantly lubricated and cooled by working liquid.

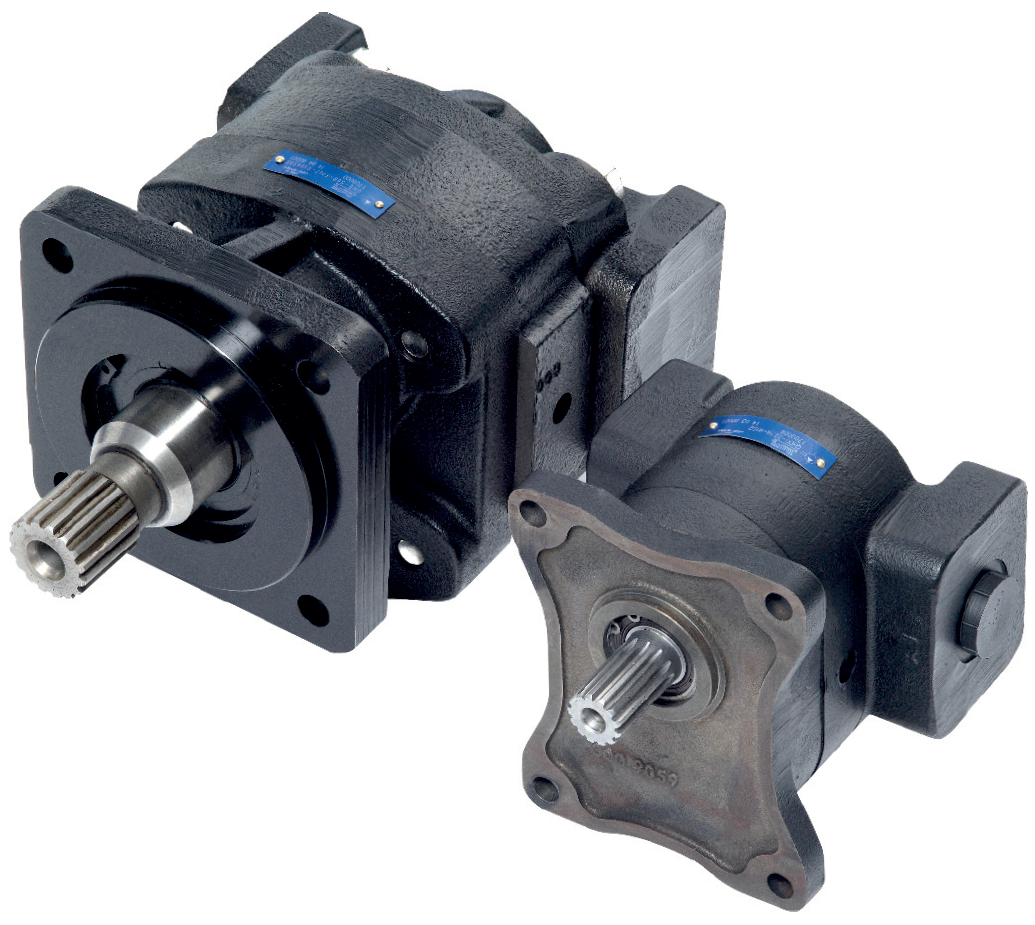

HEAVY DUTY CAST IRON PUMPS

- Displacement from 10 to 150 ccm/rev

- (from 0.61 to 9.15 in3/rev)

- Intermittent Pressure up to 320 bar (4640 psi)

- Continuous Pressure up to 300 bar (4360 psi)

- Revolutions from 250 up to 3400 RPM

- Full cast iron construction

- Multiple pumps on one shaft design

- Popular drives and ports

- Integral relief valves

- High efficiency in heavy field conditions

These pumps are characterized by a two-part or three-part all-cast-iron design. The pumps are characterized by simple construction with hydraulic pressure balance, compact dimensions and a wide range of connection types. Liners supporting gear journals are pressed into the flange and also in the cover. Gear wheels, which are optimized to achieve a low noise level, are made of high-strength steel. The flange dimensions enable a design with a shaft bearing for a higher radial or axial load of the drive.

FAN DRIVE MOTORS

- Noise reduction

- Emission reduction

- Fuel costs saving

- Power saving

- Wear-out reduction

Traditional direct – drive engine mounted fan systems consume more power than is necessary for the engine cooling. From that reason Jihostroj developed gear motors equipped with electrohydraulic proportional relief valves and electronically match fan speed with a cooling demand. This system allows variable fan speed independent of the engine speed.

FLOW DIVIDERS

- Rotary gear flow dividers

- From 2 up to 6 sections

- Sections from 0.8 up to 31 ccm

- (from 0.05 to 1.89 in3/rev)

- Balanced, unbalanced

- Cast iron or aluminium body

- High accuracy

- Proven quality in field conditions

Flow dividers are robust gear type products of cast iron or aluminium body, with or without hydraulic balancing with a fixed axial play. Their application is in solutions where it is necessary to split the flow with a sufficient accuracy regardless of the pressure ratio in the individual branches. The output branches can be fitted with the relief valves which are adjusted to the customer’s specifications. The flow dividers can be manufactured with the option of two to six sections. They can be used in construction and agricultural machines, fork lifts, excavators, etc.